well we got off the line and covered 60' .

lets look at how I look at the rest of the info ,figured I would strip it down and add data in groups just to make it simpler to understand .

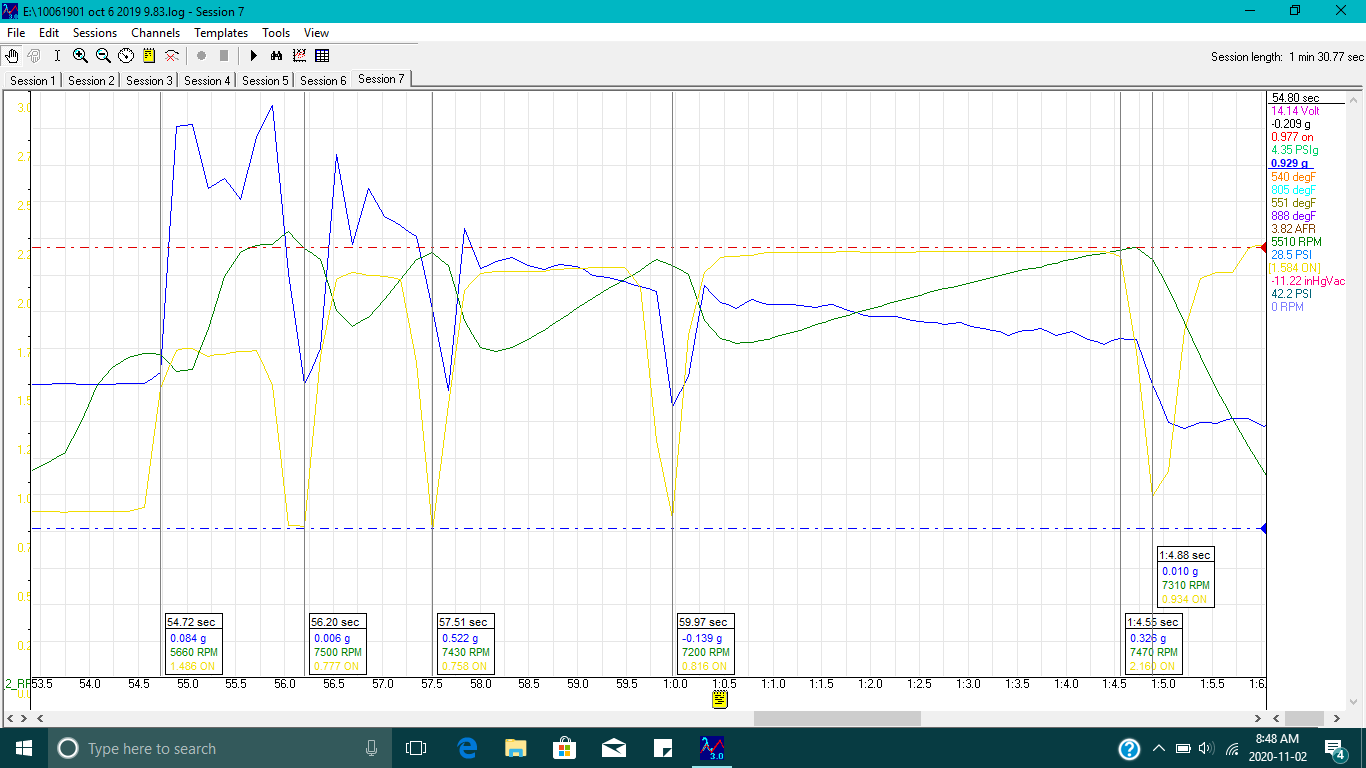

- BLUE , acceleration - GREEN , rpm - YELLOW , clutch

first info box 54.72 sec is where the run begins so add 9.83 to 54.72 and you end at 1:4.55 sec. you can see the clutch line drops/disengaged after the run is over ,Why?

that is because you always drive full throttle past the quarter line then roll of the throttle .

if you follow the info boxes you can see the stage RPM and then following to right every shift rpm .as well as you can see Acceleration slowly drops down as the 1/4 mile run continues .

of course that is normal .

Question ? could you adjust what rpm to shift at if you follow Acceleration , yes you sure can and what im looking for is a major drop off and really if you draw a line across

the BLUE acceleration line its pretty smooth and steady drop .

YELLOW- clutch I have added to tracer lines , if it represents clutch fully engaged and disengaged why is there a difference in height

. easy I have my foot on the clutch pedal , take a look at staging /first gear .car launches and I shift 1.48 sec later .yes I still have my foot on the clutch pedal .its fully engaged I just have not allowed the clutch pedal to fully come back into the freeplay zone . then 2nd and 3rd I have more time and have let the pedal almost come back fully into freeplay zone and have my foot just resting on the clutch pedal and finallythen shifted into 4th foot is right off clutch pedal .

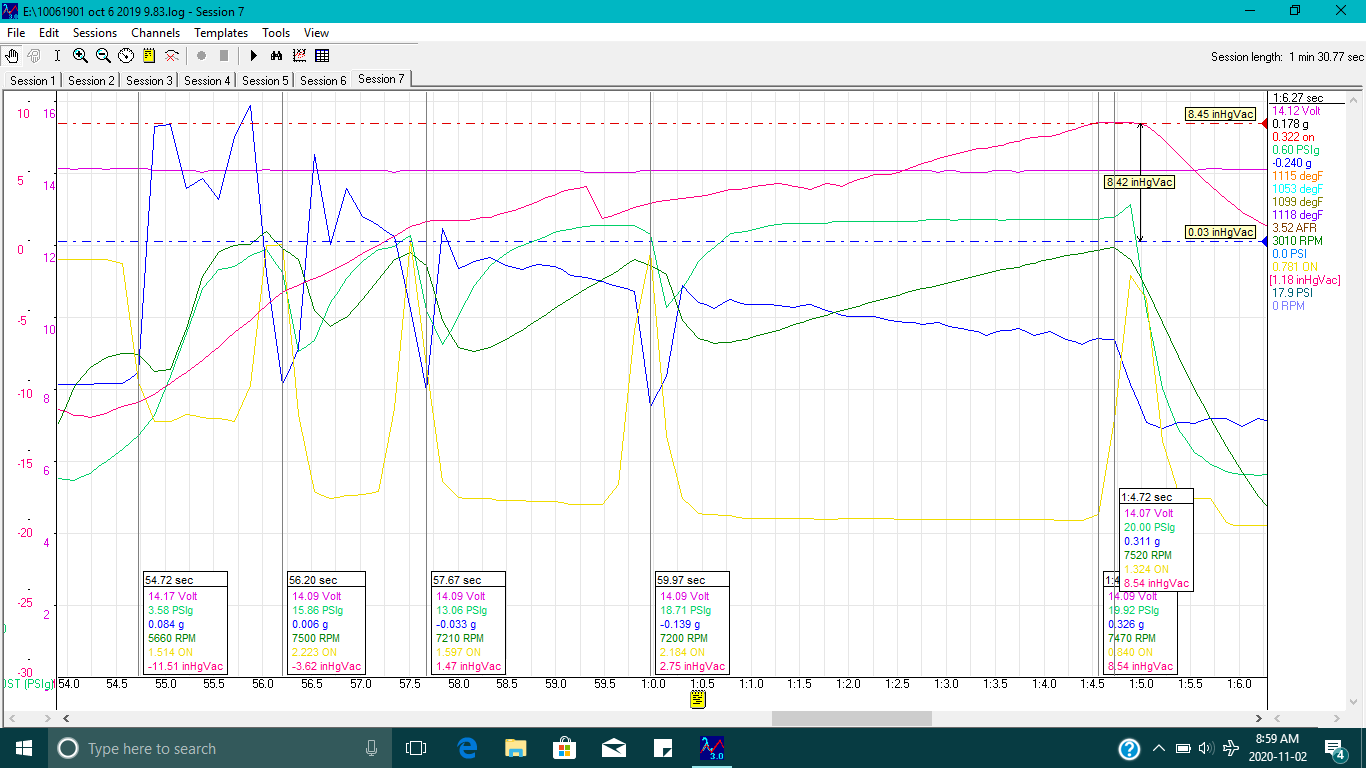

time to look at PINK- voltage and RED -vacuum . BOOST - Light Green

PINK - Voltage , yes very important to know for all the obvious reasons - a steady voltage is required to support all the electronics especially ignition .

RED - Vacuum (crankcase) I have learned more from this than anything and I have played with this for over 10 years , I know what works and what doesn't as well as what's important , I've added 2 trace lines ,the bottom dotted Blue line represents 0 pressure and the Red dotted upper line represents the max Crankcase pressure .

FYI: 1 inHgVac is= 0.5 Psi so yes I go from -12 inhgvac to + 8 inhgvac ( 4 psi) not Bad but not Good either and I know why .

so it is caused by a few things which im well aware of .

First my GZ vacuum pump that I've been running for years is in need of some help , I know it needs service and is not pulling full vacuum .its tested by deadheading the inlet at say about 2500 pump rpm , it should pull 15" vac but I only pull 10" .yep its a tad tired .

then my 2 psi crankcase backup blow off valve was temp re-shimmed as I was checking for correct sealing ( I thought I had a internal sealing issue ) .usually the valve pops open at 1.5-2psi and dumps Any Crankcase excessive pressure ,but as you can see did not happen do to re-shimming and I was depending on vacuum pump only .

and finally why is there crankcase pressure anyway , well that's what happens when inside the case pressure can't get out and I would assume after looking at the data my tired vacuum pump could not keep up and was actually a restriction . there always is and it shows I have some blow-by past the rings , not bad for dumping in 20 psi boost in a 9.8:1 compression methanol turbo engine . if I run less than 10 psi boost it hold below 0 , Nice .

So Ring seal . the motors been together for 2 years and has a lot of milage/high load passes , and I was watching my Crankcase pressure slowly rise over time which is the biggest indication of loss of ring seal or wearing vacuum pump .

Now I do/can run the motor without the vacuum pump by replacing the inlet hose that usually runs from the alternator stand outlet to the vacuum pump inlet by directly connecting the alternator stand outlet to the dry sump tank inlet and I measure no crankcase positive pressure that way , but I like the pump as it keeps my oil clean of methanol milking due to rich mixtures and prevents engine oil leaks .

Well , GREAT Vacuum data , lots to learn from . is it really a issue , Yes and No .should the motor stay below the set 10-12 inhgvac the complete pass , Yes it should but turbo methanol motors due to hugely rich mixtures are known to loose vacuum over the run .

So if and when I send the pump back to GZ for service and replace the spring in my Crankcase dump valve it in fact my motor Crankcase Pressure may in fact be not that Bad .

BUT wait there is more on this or reasons for this . gotta love data

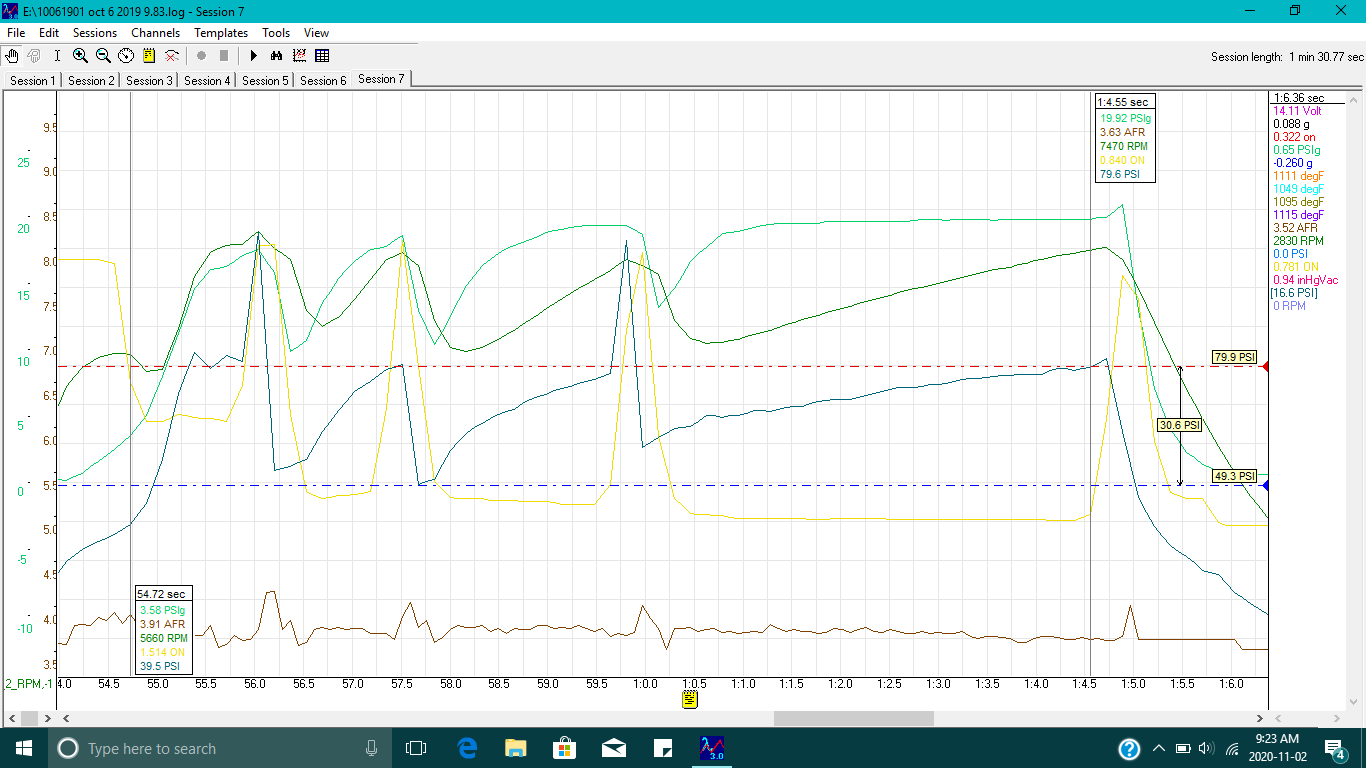

DARK GREEN - Fuel Pressure - now remember im running old school Hilborn Mechanical fuel injection (MFI) now that's another topic but for now what you need to know is , when the engines rotates so does the MFI pump which is mechanically connected to the motor ,So the faster the motor turns so does the MFI pump .which also means it generates fuel pressure at a linear rate to engine rpm , so more RPM more pressure /volume .

the pump is generating about 30 psi over the useful RPM range to a max of 80psi , the pressure sensor is connected between the MFI pump and the barrel valve . which is also display in the car on my ashtray LED readout . pump is in great shape .

DARK BROWN - AFR , now this in in the methanol scale not gasoline scale but what im looking at is in fact the total AFR number and does it trend Rich or Lean especially in the top of 4th gear under high boost ,remember I've melted my heads 2x due to lean so im schooled on safe (liking that 3.5-3.7 range ) . and you can see if you follow along in 4th gear it trends rich , GREAT that's what I want to see .