i copied this over from years ago from one of my favorite old sites ( ultimate air cooled ) used to be great ,not so much anymore but,

this was a topic from many years ago but its a good read with some great info

jim martin

my poor car is gutted but i hope to start getting it together very soon .i have access to a 4 pad car scale .I'm very worried about weight up frt this time and think i may need to transfer some up there .i have a few things that could be relocated .wondering if anyone has done a 4 corner balance and would mind not sharing some data with me ,it would be a big help as i want to remain stable and not over or under weighted at one end .info could be posted here or in private if you want to keep your results a little more guarded i can appreciate that as well .

thanks , Jim

Bad Bug Two

as far as where you want the weight, I am not as sure on that as some things that you need to consider (You may already know!)....

Make sure that when you weigh it the scales are all level to each other. There is a couple of methods to do this, but if they are not on the same plane, the car may inadvertently shift its weight to the lower scale(s). Also, make sure the car is race ready on its weight.... fuel, tire pressures, you (with all safety gear), etc....

By the way, I just weighed my race bug last week and with me in it, it is right at 1750lbs total. (I don't recall individual weights, because I was not concerned with that at this point.)

Good luck and hopefully someone else can chime in with more useful info!

Tom Simon

others may disagree, but I found a 4 scale check and adjustment to be key in car set up. Namely, getting fore and aft weights in the ball park, then getting the cross weights about right.

My experience has been with only two cars, and both handled great when finished. I ended up with 1/3 weight up front to 2/3 weight on the rear of one car. Then 'square up' the cross weights, meaning with me and my gear in the car, the front tires should each be carrying 1/6th of the total weight, the rear tires should each be carrying 1/3rd of the total weight.

If you are class racing, build a light car then put lead weights where you want it. But most guys aren't building a class car.

If you are rebuilding the car, and you have a choice, keeping/moving the battery to the passenger side, same with the fuel cell, ignition box, breather tank, etc can help offset the weight of the driver.

Before you scale, make sure the front end is aligned, tires pressures are set, driver id in the car, fuel, oil, ready to race.

Small changes to the ride height or preload of the rear torsion bars, by turning the set screws on the aftermarket spring plates is about the easiest way to change corner or cross weight readings. Crank on the passenger rear torsion set screw and the weight of the driver's side front also increases. I hope that helps

slalombuggy

haven't set up cars for straight line racing, but one thing we want in autocross and road racing is to keep all weight as low as possible and as said by Tom, try to offset as much as possible to the passenger side to compensate for drivers weight. Having the ride height set where it will be is critical in scaling a car. Any changes in that area will mean re-scaling the car.

jim martin

thanks for the info .I'm looking fwd to see what i will find out once the wheels hit the ground again .

anyone has some input let me know I'm taking safety very serious this year and everbit helps

jim martin

always like to follow up .

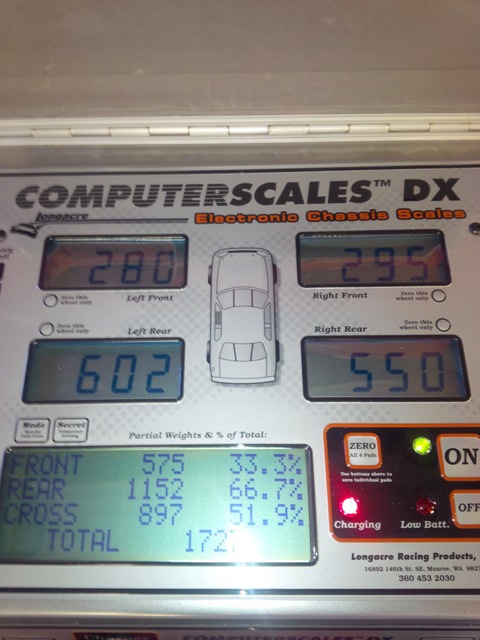

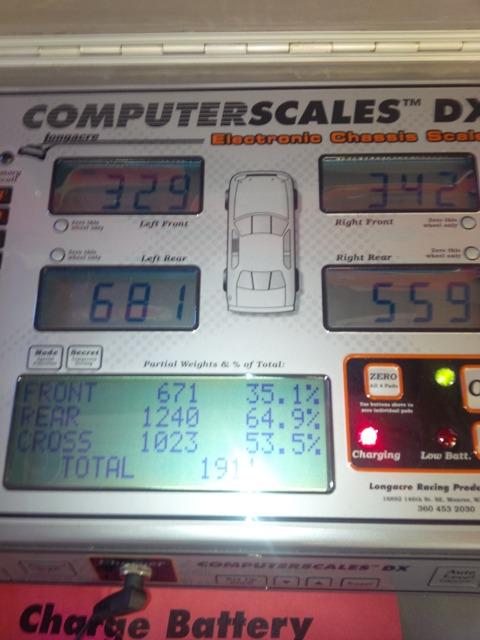

car on the scales ,with me in it, helmet on lap and suite under seat. 3 gallons fuel .

car without driver, weight 1727 lbs

with driver 1911 lbs

only thing to add is my safecraft fire suppression system . i was very surprised to see the

left frt lighter than the right frt ,especially with me on that side .numbers look good

and happy to see a 35/65 split

MagOO

Well, with a little judicous finagling, you should be able to scale it a little better than that. it may help if you can mount the snuff kit close to the battery tray area..Also do a search here on Tony Klink's PRO/GAS car session with the 4 corner..

Jabber Jaws

The drivers side torsion bar has more preload than the passenger side. The drivers side MAY have too much OR the passenger side MAY have too little. Measure the rear camber and ride height to determine which side needs adjusting.

Nick Wharton

Jabber Jaws said:

The drivers side torsion bar has more preload than the passenger side. The drivers side MAY have too much OR the passenger side MAY have too little. Measure the rear camber and ride height to determine which side needs adjusting.

you beat me to it. I was thinking the same thing. Check ride height loaded, unloaded, before and after

jim martin

i see what you are saying .by adjusting the right rear torsion firmer it will basically push/apply more weight to the right rear and in doing so will force more pressure to the left frt

Jabber Jaws

jim martin said:

i see what you are saying .by adjusting the right rear torsion firmer it will basically push/apply more weight to the right rear and in doing so will force more pressure to the left frt

Exactly, but you may find by investigating camber and ride height that LOWERING the left rear is the way to go. If it is swing axle camber will be your main factor. You want both wheels to have the same camber loaded. When you think you are done raise the front about 10 inches and see what happens in the back with weights and camber, this will give you an idea where to "shift weight" in the car and if your rear torsions are close to equal strength.

Tom Simon

jim martin said:

always like to follow up .

car on the scales ,with me in it, helmet on lap and suite under seat. 3 gallons fuel .

numbers look good and happy to see a 35/65 split

If I were doing the set up, I would try to get closer than that. I would almost ignore weight without driver and gear. It's interesting, but has little bearing on how the car will drive down track. Make sure caster and camber are set, tire pressures are set with a good gauge. Only then will your scales work correctly.

If I had them, I'd tighten the passenger (right) rear springplate adjuster screw, to add more pre-load to the right rear. If I had no adjustable spring plates, I'd take the springplate off and carefully re-index both inner and outer splines to yield a little more pre-load on the right rear. As was mentioned, increasing right-rear pre-load will always increase load on the left front, at the same time. It's very similar to shimming up the short leg of a table sitting on an uneven surface. Two legs are carrying all the weight, the other two 'short legs' are wobbling. You only shim one of the two legs, yet when finished, both legs are now carrying weight.

The goal is to make the left front and rear, and the right front and rear percentages equal, regardless of left side and right side weight (which you can't do anything about at this point, short of adding lead bars, which I can't recommend for these purposes).

Example: look at your total left side weight, and total right side weight with driver. Right side total weight, right front 342 + right rear 559 = 901lbs. Left side total weight, left front 329 + left rear 640 = 1011lbs. Unless you move the driver toward the tunnel 6", the left and right weight distribution will remain the same, driver's side is 100lbs heavier. For corner weighting purposes, let's assume you can't/won't change that fact.

Typically the left of a VW's driver's side of the car will have a higher combined front and rear weight total, so your driver's side being heavier than the passenger side is typical.

What you can do, to make the car go straight and handle great, is to get your front and rear percentages closer.

Example: as the car sits, your front/rear percentages are 35/65, which is fine. What is off, and can be fixed, is the right rear currently carries only 62% of the right side's total weight, and the left rear carries 67% of the left side's total weight. Make sense?

To fix this on your car, increase right rear preload to where the scale reads about 585lbs, the left rear should read about 656lbs. These are approximate, because the front and rear percentages usually change slightly as you increase or decrease pre-load. This is a little bit 'trial and error' so be patient, keep notes, use a calculator, and keep in mind that the goal is to have the 'corner's' carrying the right percentages of weight.

Jeff Lovell

unhook your shocks. I don't know your shock valving, so it might not make too much difference. but normally you should un hook the bottom of the shocks

Jeff Lovell

im sure you know this but make sure you bounce the car real good on all four corners , front back , side to side.

Tim Haugen

Something I have been doing to check my car is chassis tweak test.

We did this on on road and off road rc cars and have adapted it to real cars. You need to find a place on your car that is level side to side to place a 2’ level or similar on the chassis. Then you need to place the car on a level surface you may need to use shims under the tires to achieve this. This is critical, I use a 12’ level to achieve this. After you have the car on a leveled surface, get the weight in the car where it belongs, driver gas etc. Next you need to find a place to lift the car perfectly centered side to side for the front and back respectfully. Get a floor jack with a piece of angle iron place it on the jack with the triangle pointed up. Roll the jack under the car place the point of the angle perfectly on the point you located to be center. Lift one end of the car (with weight in) and watch the level. If the car is perfect it will keep level if not it will tell you what side needs adjusted. Remember to bounce the car once lifted as Jeff suggested. The next thing to check is your droop ( the amount the wheels drop when that end is lifted) If the chassis level shows the car to be level the droop should be the same. If not, you need to address the droop situation also. Scales don’t show this and it is critical to the cars balance. Redo for the other end and recheck. If done correctly you will notice how much better the car will launch and drive. I have done this to all the cars I set up and it is blatant when you drive them, there much better. I have checked my work against scales and really was not surprised at how well this works as the scales showed it.

jim martin

thanks , i completely understand and appreciate everyones input .Tom your calculations examples are excellent .

alignment is finished and rear is custom IRS with very little camber change through range of motion and in the area its sitting there would be almost Nil if i raise it or lower it 3/4 ".spring plates are adjustable left and right and all 4 corners are qa1 dual adjustable shocks .i did not recheck pressure in the tires and i now see how that can effect things .this was my first shot on the scales and will be playing with it again soon .vehicle is apart as the tranny needed a quick fix .also will level all the scales on the floor and make sure there all at the same height . also will let the shocks hang as suggested .

i would say my only adjustments at this point in which i have to play with are .removal of the steel engine deck lid , muffler , and positioning of my 5 lb safecraft bottle ,frt beam centre adjusters and of course left and right rear torsion bar adjustments .