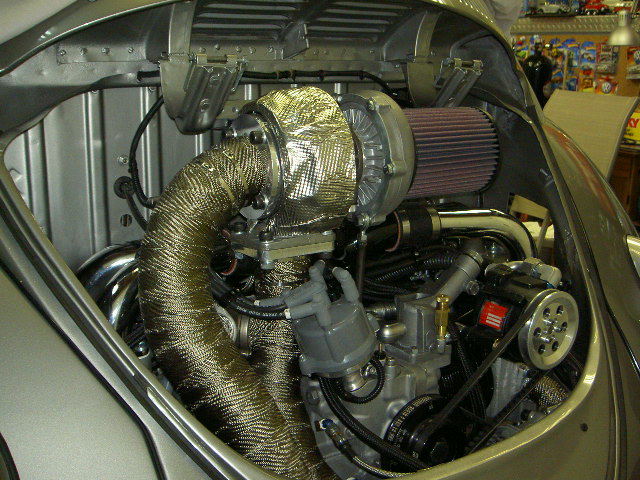

all the major modifications and fabrication and upgrades to make this motor work in the WOK are done , friggen about time .i must admit it looks unbelievable and i cant wait to fire it up .and its been fun making all the upgrades and bits and pieces along the way but it all needed doing and redoing .one thing I've done is tried to made sure everything is accessible and serviceable so it can easily be worked on , yes its friggen tight in there with all the lines etc but it seams to work, and I've had to get in and remove parts more than once so i can install another many times without any major hassles.so far so good .

sorry for the bad photos but lets get caught up .

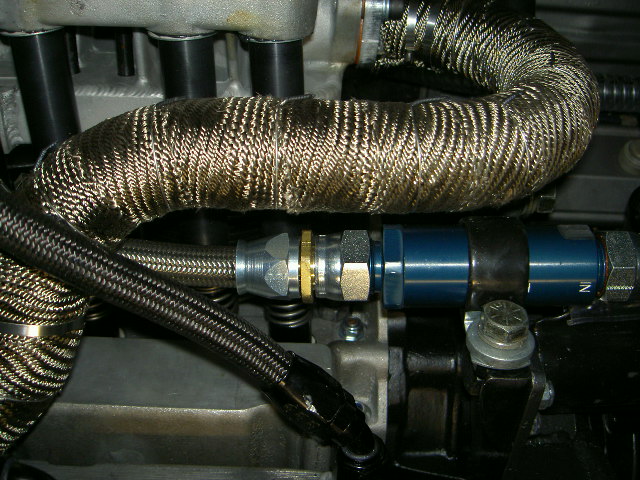

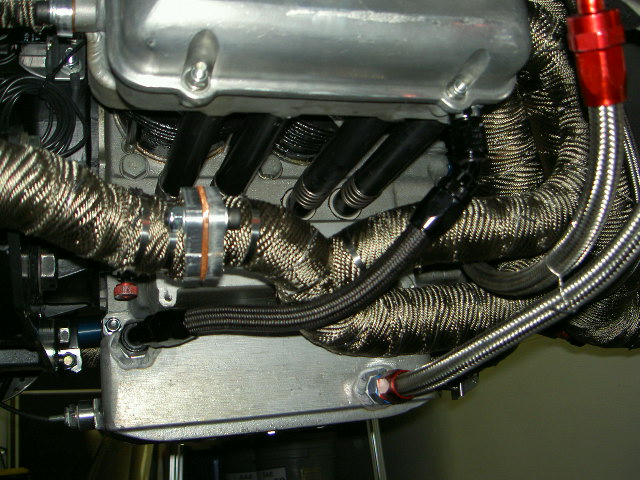

- the 4 lines coming up are for oil temp/oil pressure/engine vacuum/boost pressure.

was nice i was able to use old holes and not have to plug them up or better yet drill more .I've been pretty lucky as my poor car has had so many motors upgrades there's more mounting holes and guide holes then i can count from all the bits added or removed .that's speed i guess

- the breather after it leaves the tank connects to a coiled line that is chemical safe and exits in the same old place under the vehicle and is capped with a small k&n filter to prevent dust and dirt entre

- the AN-12 as well as the other 3 lines exit in the same point as before which is through a hole to the right of the transmission .the fuel supply sneaks in behind the breather tank and connects to a Hilborn in-line fuel filter .the 3 lines on top are the fuel return,boost pressure and oil pressure lines.and the oil temperature probe is in the lower frt right of the sump.

- over the header and connecting to a 90 and a T fitting before finally getting to the pump .the red valve valve is T'd into the fuel supply so i can easily drain the complete fuel system for flushing and maintenence when needed .

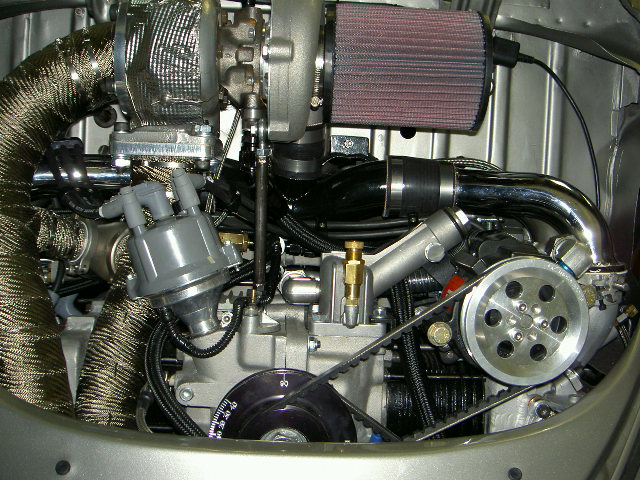

- talking about making things accessible .there is going to be a huge learning and tuning curve with this motor , one thing i have done is resprung the wastegate unit ,gotta walk before we can run .so this means removal and instillation of the wastegate unit will happen multiple times and even thou it looks like it wont ever come out it removes easily and can be out and apart on the bench in less than 15 min , see if you can see it in some later photos .the turbosmart wastegate was original set with 14 lbs worth of springs .it was decided to pull it apart and set the waste gate to 7 lbs worth of springs and get my plumbing and boost controller operating 100% before stepping up .its a very simple unit and comes with a nice ring wrench and you simply spin the aluminum ring off and separate the top cover and add or remove springs .this also allowed me to rotate the top and bottom port positions to give better line placement which made connecting the wastegate to the solinoid simple .

there are 2 basic ways to plumb this wastegate .based on whether the turbo system has high or low back pressure , i was originally plumbed for high backpressure but had some questions and after talking with Marty at turbosmart things got cleared up and i became allot wiser .so i will take his advice and plumb for low backpressure for the first run as it wont hurt a thing and will give a great starting point to get things operating smoothly .now i'm no expert as there is so much science to do with turbo sizing etc ,but i'm pretty hip to how the whole boost control thing works and in a nutshell goes like this .the wastegate spring sets the min boost your system should in theory make .for me i should make 7 lbs of boost with the 7 lb spring .and at that point the boost pressure will overcome the 7 lb spring and open the wastegate and bypass exhaust gases past the exhaust impeller and directly out the tailpipe ,this slows the turbo and of course decreases boost inlet pressure and maintains 7 lbs in the system .now this is where i will now learn if my system is indeed high back pressure or not .if i cannot make anywhere close to my 7 lbs of boost that would possibly mean my exhaust system up to the point of the exhaust impeller is backing up causing a positive pressure in the exhaust system and that positive pressure would push against the 7 lbs of spring pressure and help lift the wastegate valve off its seat prematurely and cause the exhaust to bypass the exhaust impeller sooner and slow the turbo down and of course drops boost pressure way down .so i would either need to increase the spring strength or go back to the high backpressure plumbing as before .the high backpressure plumbing simply puts some boost pressure to the top of the wastegate housing and aids the spring in keeping the wastegate valve closed allowing the system to build its set boost level , all of course this is in theory and needs testing .

this is when i was figuring the lines out and missing is the one 90 deg on the centre port .and its just a matter of moving the lines around and i can switch from the low or high system backpressure plumbing in minutes .this setup is for the high backpressure setup

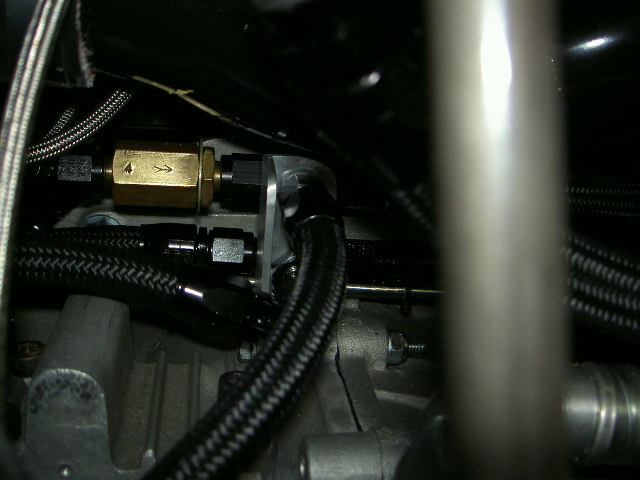

- fuel shutoff installed and plumbed before the fuel metering block .need to figure out where i'm going to mount the fuel cut lever in the car before ordering cable .

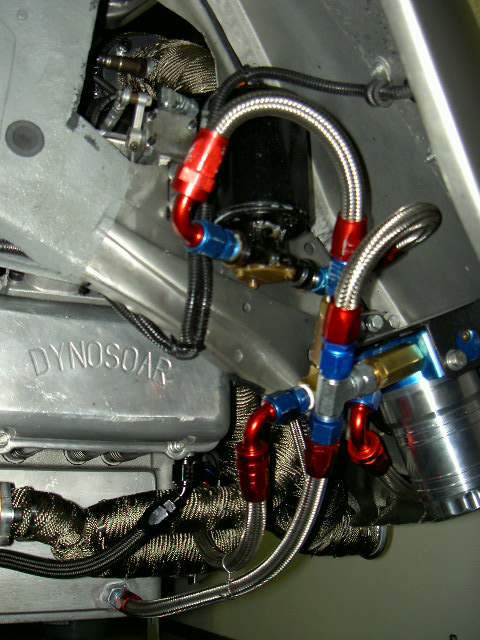

- fuel return and bypass lines , a easy bracket to make and stops everything from floppin around

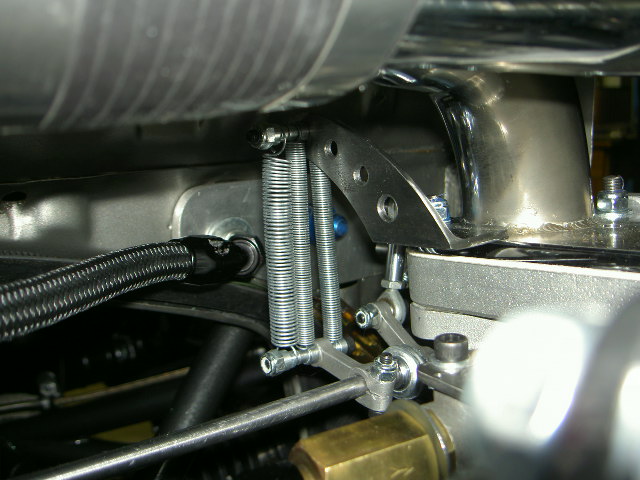

- throttle return spring and bracket setup , 1 per side . added the 3rd spring just in case

- all the plumbing's in on the left side .lots' hose

-at least the plug wires are in ,#1 and #3 are a bit tuff to get to .hope i can get the plugs out

-there so much going on i figured toss up some photos and you can figure it out

- complete , just need to put the last firewall grommets in and make a bracket for the LM1 cable and install the case vacumm line

now its time to finnish the wiring and put it on the scales .