Well, a contract in January turned into another contract in February, and that turned into an event in March...and just like that, I'm almost three months down on car time

On the plus side, thanks to these contracts I've driven some absolutely incredible roads and crossed things off my bucket list. I've driven through Pennsylvania, Maryland, Virgina, North Carolina, South Carolina, Georgia, Florida, Alabama, Tennessee, Kentucky, Ohio and Michigan.

I've visited Barber Motorsports Park (including laps of the track, tour of the museum and a special tour of the museum workshop), BMW club of America's museum, The Lane Museum, Rick Hendrick's private collection, The Corvette Museum, The Amelia Island Concours and the Kennedy Space Centre.

I've been lucky to tour some pretty incredible automotive shops as well. The Creative Workshop in Florida was unbelievable. Wood floors, a hidden dyno, and cars you only dream of. Detroit speed builds some incredible muscle cars of the SEMA-type...but the sneak peak at this year's SEMA cars was pretty exciting. White Post Auto Restorations might be the oldest restoration shop in the USA and four generations have owned/worked/run the place. Duncan Imports is a car-guys dream where the warehouses of cars just goes on, and on, and on. How about a beetle with less than 30 miles on it? How about four of them...from three different decades. Unreal.

But alas, it means the poor Rally Bug has just sat without me. Having finally returned home, I've been crunching away on it as much as possible. Photos are limited, as I'm trying to get the work done vs. document it.

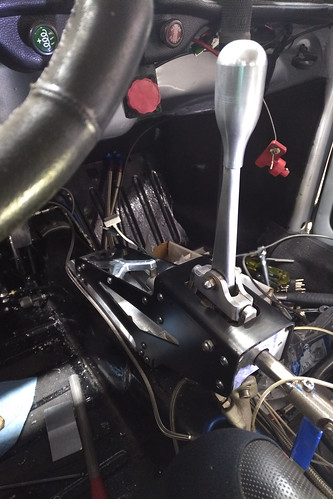

Moving the shifter back 2" resulted in some interesting issues. First off, the mount on the transmission tunnel suddenly had a tonne of flex in it. Previously each of the mounting bolts (three of them) were "boxed in", but the move back results in flex I definitely didn't anticipate. Fortunately the addition of two extra bolts, and a 2" gusset welded between mount and trans tunnel resulted in a flex-free install. The carbon shift rod I built needed to be shortened, which was a bit of a pain since I had to rescue the aluminum end I had bonded in originally. Without my buddies lathe, there was no way to whip up a new one. Managed to shorten the rod without shattering it...and then got to do it all over again as I cut it a 1/4" too long!

With everything installed in place, I discovered a new problem…the shift rod angle is just steep enough that it was hitting something in the tunnel. I ended up cutting out a little more than I wanted, but worked out it was the throttle cable tube (figures, the only one I CAN’T cut out). Ended up having to cut the tube so I could move it, and then weld in a section to keep it inline so the cable won’t get cut.

Extended the brake light harness, since the switches are now inside the cabin, in front of the shifter.

Suspension has been re-installed, with all new bushings…simply because I was in there.

Hmmm…it would seem this box was not the correct set of wheel studs. Where the heck are my 25mm studs!?!

And taking care of some details…trying to freshen it up a little.

Fresh coat of black on the bottom of the chassis. I hate this job, but rather then patch some sections that needed it, I cleaned the whole chassis and painted it from front to back.

Under-dash area is now ready to go, and looking the business.

No photos, but I fired it up after it's winter break and started tuning the cold-idle a little bit on the fuel injection. There's still no fluid in the brake or clutch system, so I couldn't take it out for a real warm-up.

Found a couple of stripped out bolts in the front transmission mount while doing a nut-and-bolt check on the car. Drilled, helicoiled and new bolts installed. We'll see how that goes. It may explain why I've broken one of the kafer bar mounts twice previously, and again before the winter. Welded and reinforced that bracket, so we'll see what breaks next

Dealt with some wiring in the front end, and then looked over at the seat you can see in the floorpan photo above. I had a pair of those OMP seats with the headrest in the car for the Retro-Cars shoot many years ago, and the Cobra Imola 2 seat I'm using is looking quite worn. So, after perfecting the driving position after the pedal install, I of course decided to swap the seat out. Sigh. Fortunately I was able to get the seat in a position that I think will work well. Getting in and out of the car with the headrest is going to be annoying, so I doubt this seat will last long!

Retorqued the heads, and checked the valve train. I have some oil leaks which appear to be coming from the headstuds(?), but didn't show up when I started the car and idled it for 20min (after retorquing the heads). I have a sneaking suspicion the engine is coming out after the road test to find the leak

Tomorrow I should get my Motive brake bleeder back, and I can get the car back down on it's wheels. Need to do a front end alignment, and then I should be able to road test it.

-Dave